Engines and fuels¶

Otto cycle¶

- Gasoline engines

- 4-stroke cycle

- Intake

- Compression

- Combustion at the top

- Expansion/power

- Exhaust

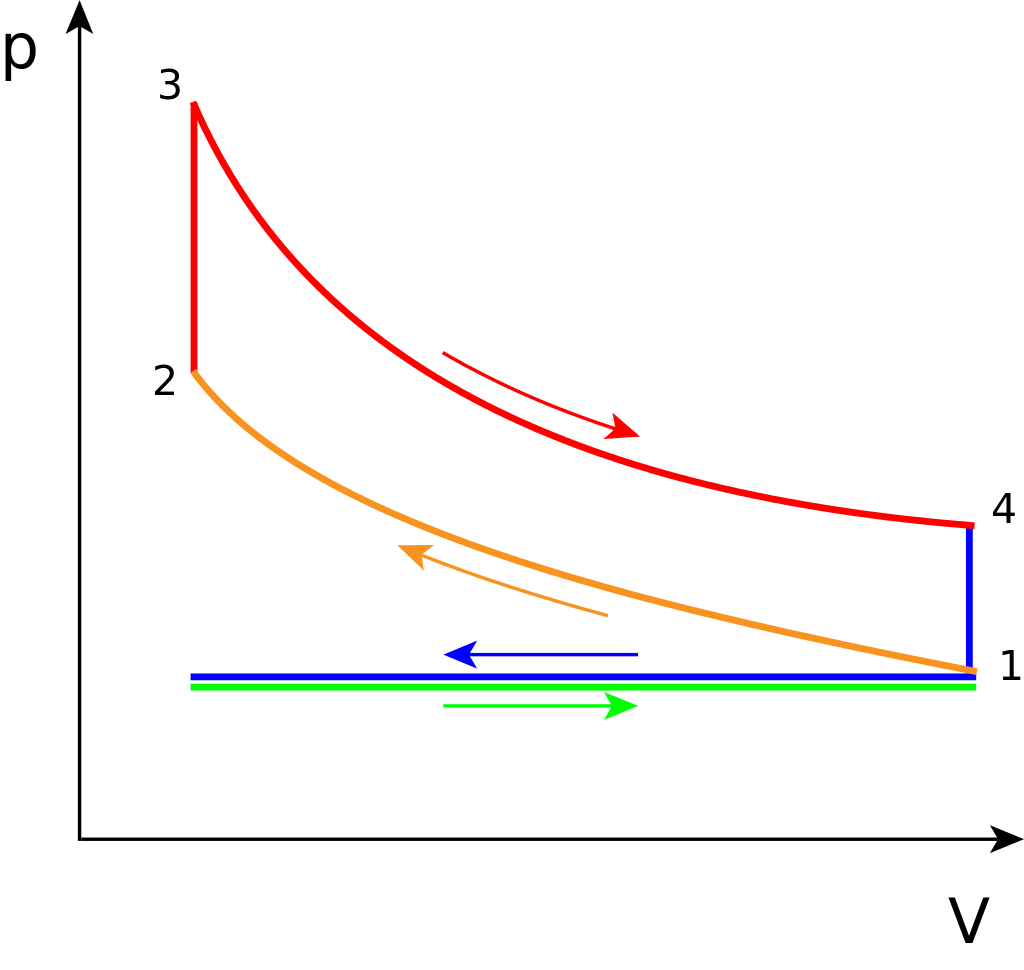

Idealized cycle¶

- 1$\rightarrow$ 2: ideal compression

- Adiabatic, PV work required by the engine.

- 2$\rightarrow$ 3: sensible energy added through burning of the fuel/air mixture

- Combustion assumed to occur quickly, at constant volume. Pressure rises.

- 3$\rightarrow$ 4: ideal expansion

- Adiabatic, PV work produced by the engine.

- 4$\rightarrow$ 1: heat rejection

- drop in pressure as the valve is opened at the bottom of the stroke.

- exhaust and intake are the horizontal blue and green lines.

Net work¶

- The net work produced is the area under curve 3$\rightarrow$4 minus the area under curve 1$\rightarrow$2.

- Since the compression and expansion are adiabatic, the work is equal to differences in internal energy $u$.

- Work required for compression: $W_c=u_2-u_1$.

- Work done by expansion: $W_e = u_3-u_4$.

- Net work performed by the engine = $W_e-W_c = (u_3-u_4)-(u_2-u_1)$.

Note that $u_2=u_3$ since process 2$\rightarrow$3 is adiabatic and constant volume. The "heat added" step is really sensible energy generated by combustion. But the internal energy of the mixture remains fixed.

Adiabatic compression and expansion.¶

- Assume ideal gas and adiabatic compression/expansion.

$$du = dW = -PdV$$

$du = c_vdT$ $$c_vdT = -PdV$$

$P = RT/V$, rearrange

$$\frac{dT}{T} = -\frac{R}{c_v}\frac{dV}{V}$$

- $R = c_p-c_v$, $\gamma = c_p/c_v$.

- $\rightarrow$ $R/c_v = \gamma -1$.

$$\frac{dT}{T} = -(\gamma-1)\frac{dV}{V}$$

- Assume $\gamma$ is constant. Then integrate to

$$\ln\frac{T_2}{T_1} = -(\gamma-1)\ln\frac{V_2}{V_1}$$

Rewrite as $$\frac{T_2}{T_1} = \left(\frac{V_1}{V_2}\right)^{\gamma-1}$$

Using $P=RT/V$, and expressions for $\gamma$ above, we have $$\frac{T_2}{T_1} = \left(\frac{P_2}{P_1}\right)^{(\gamma-1)/\gamma}$$

Similarly $$P_1V_1^\gamma = P_2V_2^\gamma$$

If we relax the assumption that $\gamma$ is constant, we have $$\ln\frac{V_2}{V_1} = -\int_{T_1}^{T_2}\frac{c_v(T)}{RT}dT$$

Example¶

- Compute the work and efficiency on a lower heating value basis for an Otto cycle with a stoichiometric methane-air mixture.

- Use a compression ratio (CR) of 10. That is $V_1/V_2 = V_4/V_3 = 10$

- code below requires streams.py and cantera

from streams import streams

strm = streams({"O2":1,"N2":3.76}, {"CH4":1}, 300, 300, 101325, "gri30.xml")

CR = 10

#----------- state 1: cold, atmospheric reactants

strm.set_gas_mixing_state(strm.ξst)

P1 = strm.gas.P

T1 = strm.gas.T

u1 = strm.gas.int_energy_mass

#----------- state 2: compress reactants

strm.set_gas_state_adiabatic_compression_expansion(1/CR)

P2 = strm.gas.P

T2 = strm.gas.T

u2 = strm.gas.int_energy_mass

#----------- state 3: burnt products

strm.gas.equilibrate("UV")

P3 = strm.gas.P

T3 = strm.gas.T

u3 = strm.gas.int_energy_mass

print(f'NO = {strm.gas.Y[strm.gas.species_index("NO")]*1000000:0f}')

#----------- state 4: expanded products

strm.set_gas_state_adiabatic_compression_expansion(CR)

P4 = strm.gas.P

T4 = strm.gas.T

u4 = strm.gas.int_energy_mass

print(T4, P4)

strm.gas.equilibrate("UV")

print(strm.gas.T, strm.gas.P)

print(f'NO = {strm.gas.Y[strm.gas.species_index("NO")]*1000000:.1f}')

#----------- work and efficiency

W = (u3-u4) - (u2-u1) # J/kg mixture

LHV = strm.get_LHV_pCC() # J/kg fuel

η = W/strm.ξst/LHV # efficiency; ξst is used to convert W from J/kg mix to J/kg fuel

print(f"η = {η:.2f}")

print(f'P1 = {P1/101325:.2f} atm, T1 = {T1:.0f} K')

print(f'P2 = {P2/101325:.2f} atm, T2 = {T2:.0f} K')

print(f'P3 = {P3/101325:.2f} atm, T3 = {T3:.0f} K')

print(f'P4 = {P4/101325:.2f} atm, T4 = {T4:.0f} K')

NO = 7249.681704 1581.0497304280195 541668.9741244201 1834.455938236005 619897.2037123383 NO = 193.1 η = 0.43 P1 = 1.00 atm, T1 = 300 K P2 = 23.02 atm, T2 = 691 K P3 = 96.24 atm, T3 = 2846 K P4 = 5.35 atm, T4 = 1581 K

- A compression ratio of 5 gives $\eta=0.33$

- $P_2=9$ atm, $T_2=546$ K

- A compression ratio of 10 gives $\eta=0.43$

- $P_2=23$ atm, $T_2=690$ K

- At high CR, the high $T_2$ can lead to auto-ignition and engine knock, which can cause damage.

- For methane-air, $\gamma=1.37$

Octane rating¶

- See Wikipedia for lots of information

- The octane number is the percent of iso-octane (by volume) in a mixture of iso-octane and n-heptane, that has the same knock characteristics as the given fuel.

- A higher octane number indicates a fuel that is more resistant to knock.

- There are several different measurement methods, including the "Research Octane Number" and the "Motor Octane Number", an average of which is used in the U.S.

- It is possible to have an octane number greater than 100.

- Higher octane numbers can tolerate higher compression ratios.

- Elevation matters.

Review article on impact of fuel molecular structure on auto-ignition¶

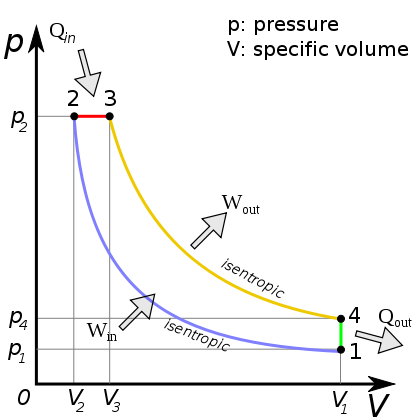

Diesel cycle¶

https://en.wikipedia.org/wiki/Diesel_cycle#/media/File:DieselCycle_PV.svg

https://en.wikipedia.org/wiki/Diesel_cycle#/media/File:DieselCycle_PV.svg

- 4 strokes

- Compress only air $\rightarrow$ hot

- Then inject fuel $\rightarrow$ autoignition, but the injection timing is controlled.

- No knock issue, allows cheaper fuels.

- High compression radio gives higher efficiency.

- CR = 12-24.

- In the diagram above, the combustion step 2$\rightarrow$ 3 occurs with some piston travel $\approx$ constant pressure.

- Heat steps $Q$ again refer to release of sensible energy, and exhaust/intake.

- In the code above, change the

equilibrate("UV")toequilibrate("HP")

Other cycles¶

- Brayton cycle (gas turbines)

- Rankine cycle (steam cycle, e.g., coal plants)

Fuels¶

Compare diesel fuel and gasoline

Diesel: about 25% aromatics, $C_{12}H_{23}$, ($C_{10}H_{20}$ - $C_{15}H_{28}$)

Gasoline: about 35% aromatics, $C_8H_{18}$, ($C_4$ - $C_{12}$)

$\rho_D\approx 0.85$ kg/L, versus $\rho_G\approx 0.72$ kg/L

Heating value: $HV_D\approx 38.6$ MJ/L versus $HV_G\approx 34.9$ MJ/L

Heating value: $HV_D\approx 45.4$ MJ/kg versus $HV_G\approx 48.5$ MJ/kg

On an equal mass basis, the large differences in efficiency are due to diesel having higher compression ratios.

Ethanol additives reduces hydrocarbon emissions (volatile organic compounds, VOCs)

Exhaust gas recirculation (EGR)¶

- $NO_x$ is a pollutant formed at high temperatures.

- To reduce $NO_x$, reduce peak flame temperatures.

- One way to do this is by recirculating cool exhaust gases into the reaction mixture. This increases the heat capacity and reduces the flame temperature.

- Also reduces efficiency.

- Very common in diesel engines.

- Up to 50% EGR

- In SI engines, only 5-15% EGR

Recuperation/Regeneration¶

- Raise flame temperatures by preheating reactants (air).

- Exchange heat with hot combustion products.

- High temperature applications, glass furnaces.

https://www.glassonweb.com/news/nsg-cold-repair-float-glass-furnace-us

https://www.glassonweb.com/news/nsg-cold-repair-float-glass-furnace-us

1-(T1/T2)*(T4/T1-1)/(T3/T2-1)

0.405768344464696